Introduction

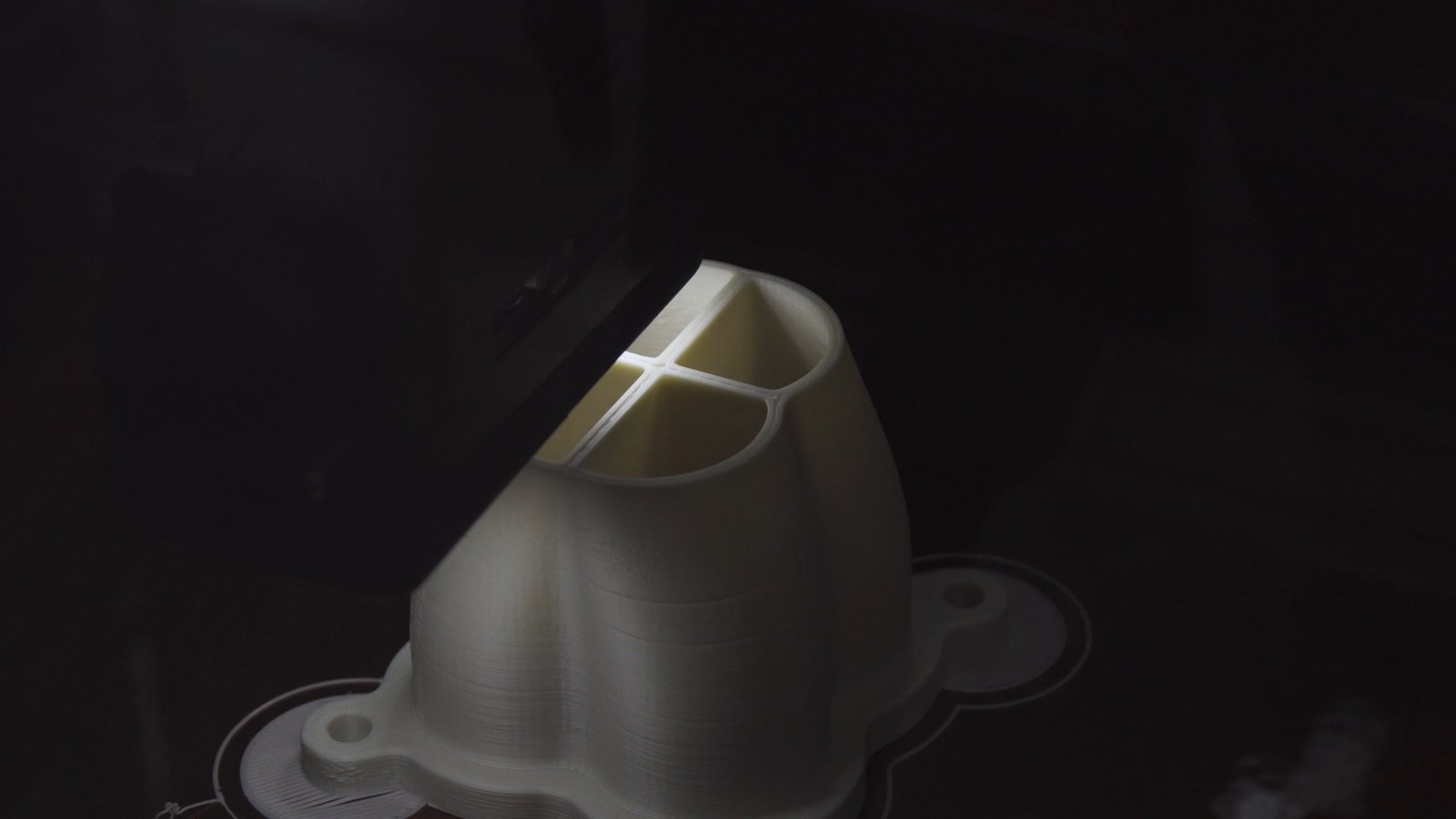

When it comes to FDM (Fused Deposition Modeling) 3D printing, the nozzle plays a crucial role in determining the overall printing quality and efficiency. In this blog post, we will dive into the world of FDM nozzle sizes and explore the pros and cons of different materials used for these nozzles.

FDM Nozzle Sizes

The size of the FDM nozzle refers to the diameter of the opening through which the filament is extruded. Common nozzle sizes range from 0.2mm to 1.0mm, with smaller sizes providing greater precision and larger sizes enabling faster printing.

1. 0.2mm Nozzle: This nozzle size is ideal for highly detailed prints that require intricate designs. It offers excellent precision but can be prone to clogging, especially when using materials with additives or impurities.

2. 0.4mm Nozzle: The 0.4mm nozzle is the standard size that comes with most 3D printers. It strikes a balance between printing speed and detail. It is suitable for a wide range of applications and is less prone to clogging compared to smaller nozzles.

3. 0.6mm Nozzle: This nozzle size is ideal for fast printing of larger objects. It sacrifices some detail but significantly reduces printing time. It is commonly used in prototyping and manufacturing industries.

4. 1.0mm Nozzle: The 1.0mm nozzle is the largest commonly available size. It is used for rapid, low-detail prints or when printing with materials that contain particles or fibers. It allows for faster extrusion and is less susceptible to clogging.

Pros and Cons of Different Nozzle Materials

FDM nozzles are typically made from three different materials: brass, hardened steel, and stainless steel. Each material has its own set of advantages and disadvantages.

Brass Nozzles

Pros:

- Excellent heat conductivity, allowing for faster heating and better temperature control.

- Cost-effective and widely available.

- Works well with most commonly used filaments.

Cons:

- Less durable compared to steel nozzles, particularly when printing with abrasive materials.

- Prone to wear and deformation over time, leading to decreased printing quality.

Hardened Steel Nozzles

Pros:

- Highly resistant to wear, making them suitable for printing with abrasive materials like carbon fiber or metal-filled filaments.

- Longer lifespan compared to brass nozzles.

Cons:

- Poor heat conductivity, resulting in slower heating and potential issues with temperature control.

- More expensive than brass nozzles.

Stainless Steel Nozzles

Pros:

- Good heat conductivity, enabling faster heating and better temperature control compared to hardened steel nozzles.

- Resistant to wear, making them suitable for printing with abrasive materials.

Cons:

- Less durable compared to hardened steel nozzles.

- More expensive than brass nozzles.

Choosing the right FDM nozzle size and material is essential for achieving the desired printing results. Whether you prioritize precision, speed, or the ability to print with abrasive materials, understanding the pros and cons of different nozzle sizes and materials will help you make informed decisions. Remember to consider the specific requirements of your project.