The rise of 3D printing technology has revolutionized the manufacturing industry in ways previously unimaginable. It has brought about a shift towards local manufacturing, eliminating the need for long-distance shipping and significantly reducing global emissions. This article explores the fundamental role of 3D printing in reshaping the manufacturing landscape within North America, and its positive impact on the environment.

Local Manufacturing: A Sustainable Solution

Traditionally, manufacturing involved mass production in large factories and shipping products across continents. This process resulted in high transportation costs and significant carbon emissions. However, 3D printing has challenged this model by enabling localized production.

With 3D printing, products can be manufactured on-demand and closer to the consumer, reducing the need for long-distance shipping. This not only saves time and money but also has a profound impact on the environment. Local manufacturing reduces the carbon footprint associated with transportation, as products are produced and delivered within a shorter distance, resulting in lower emissions.

Empowering Small-Scale Manufacturers

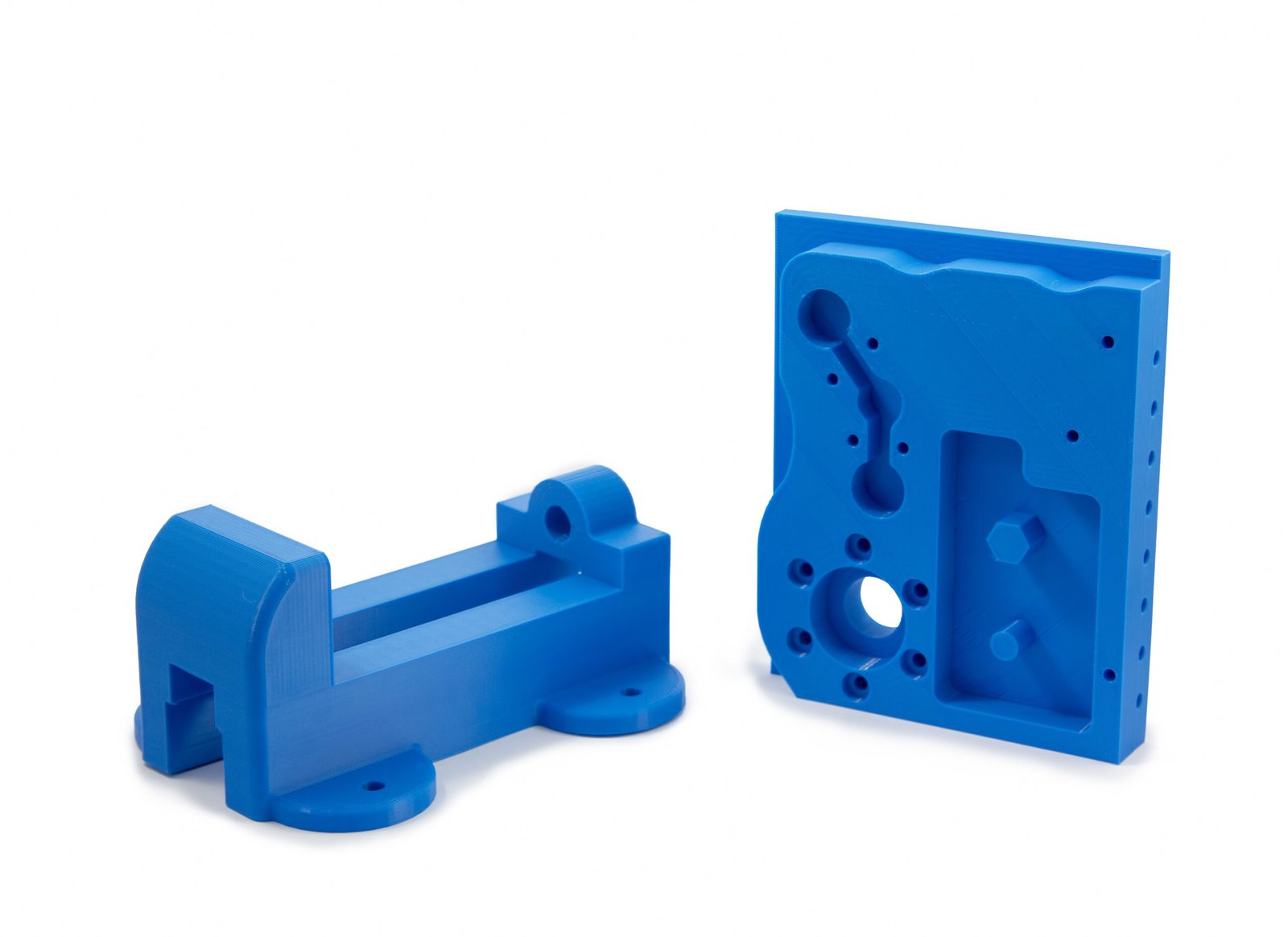

Another significant advantage of 3D printing is its ability to empower small-scale manufacturers. In the past, large corporations dominated the manufacturing industry due to economies of scale. However, 3D printing has leveled the playing field, allowing smaller businesses to compete on a global scale.

By adopting 3D printing technology, small-scale manufacturers can produce high-quality products without the need for expensive machinery or extensive facilities. This accessibility promotes local manufacturing, as smaller businesses can now create customized products for their local markets. This shift towards localized production not only stimulates local economies but also reduces the need for global shipping, resulting in decreased emissions.

Customization and Waste Reduction

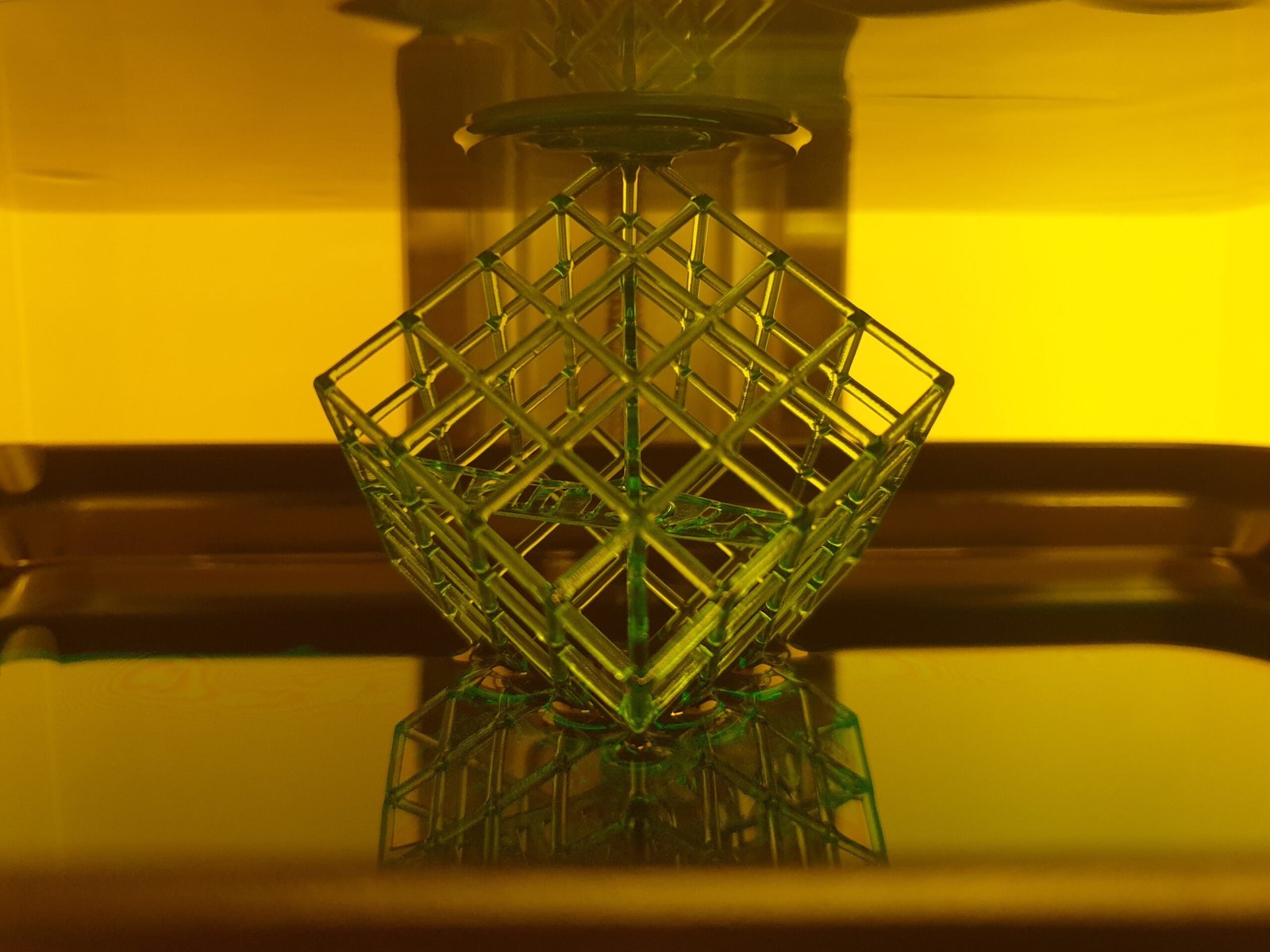

One of the most significant advantages of 3D printing is its ability to enable customization. Traditional manufacturing methods relied on mass production, leading to excess inventory and waste. However, 3D printing allows for the production of personalized products, eliminating the need for excessive stock and reducing waste.

By manufacturing products on-demand, businesses can significantly reduce their environmental impact. 3D printing enables precise material usage, minimizing waste generation. Additionally, the ability to create custom-fit products reduces the need for returns and exchanges, further reducing carbon emissions associated with reverse logistics.

The Future of Manufacturing

As the environmental impact of global shipping becomes increasingly apparent, the importance of localized manufacturing cannot be overstated. 3D printing technology is at the forefront of this shift, enabling businesses to produce goods locally and reduce their carbon footprint.

With advancements in 3D printing materials and capabilities, the future of manufacturing looks promising. As more businesses adopt this technology, the environmental benefits will continue to grow. Local manufacturing not only reduces emissions but also fosters innovation, encourages job growth, and strengthens local economies.

Conclusion

3D printing is fundamentally reshaping the manufacturing industry within North America. By enabling local production, it reduces the need for long-distance shipping and significantly decreases global emissions. This technology empowers small-scale manufacturers, promotes customization, and minimizes waste, all while fostering sustainable economic growth. As we embrace the role of 3D printing in manufacturing, we move towards a more environmentally conscious and locally focused future.