When it comes to 3D printing, there are several methods available, each with its own unique features and advantages. In this blog post, we will compare and contrast two popular 3D printing methods: SLA (Stereolithography) and FDM (Fused Deposition Modeling).

Origins of SLA

SLA, one of the oldest 3D printing methods, was developed in the early 1980s by Chuck Hull, the co-founder of 3D Systems. Hull’s invention revolutionized the manufacturing industry by introducing a technique that used liquid photopolymer resins to create solid objects layer by layer.

Origins of FDM

FDM, on the other hand, was developed by Scott Crump in the late 1980s. Crump, the co-founder of Stratasys, designed the first FDM 3D printer using a process that involved extruding thin layers of thermoplastic material through a heated nozzle. This method allowed for the creation of complex objects in a cost-effective manner.

Comparison of SLA and FDM

Now let’s dive into the comparison of SLA and FDM in terms of their features and applications:

1. Printing Technology

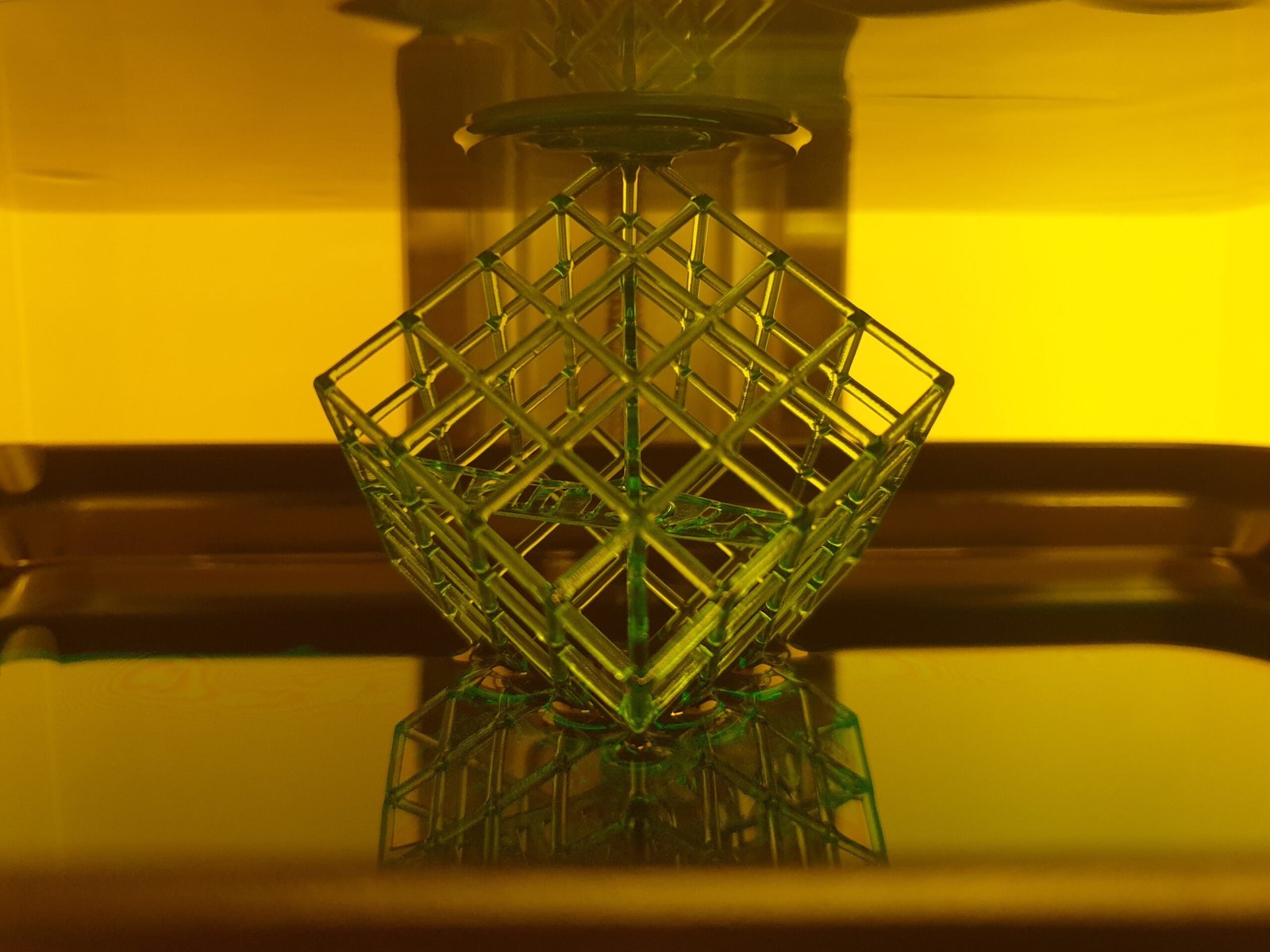

SLA uses a laser or projector to solidify liquid resin, while FDM melts and deposits thermoplastic filament through a nozzle. This fundamental difference in printing technology results in variations in print quality and speed.

2. Print Quality

SLA offers higher resolution and smoother surface finishes compared to FDM. The laser-based printing process allows for intricate details and fine textures, making SLA ideal for creating prototypes, jewelry, and dental models. FDM, on the other hand, may produce visible layer lines and rougher surface finishes.

3. Material Options

SLA supports a wide range of materials, including various types of resins with different properties such as flexibility, transparency, and durability. FDM primarily uses thermoplastics like ABS and PLA, but advancements have led to the availability of more materials like nylon, PETG, and even metal-filled filaments.

4. Print Speed

FDM is generally faster than SLA due to the layer-by-layer extrusion process. However, the print speed can vary depending on the complexity of the design and the desired level of detail.

5. Cost

SLA printers are generally more expensive than FDM printers, both in terms of upfront cost and material expenses. The cost of resin used in SLA printing is typically higher than that of filament used in FDM printing.

Conclusion

Both SLA and FDM have their own strengths and applications. SLA is well-suited for projects that require high resolution and smooth finishes, while FDM is more cost-effective and versatile with its material options. Understanding the differences between these two 3D printing methods can help you choose the right one for your specific needs and budget.